jicaseman89

Member

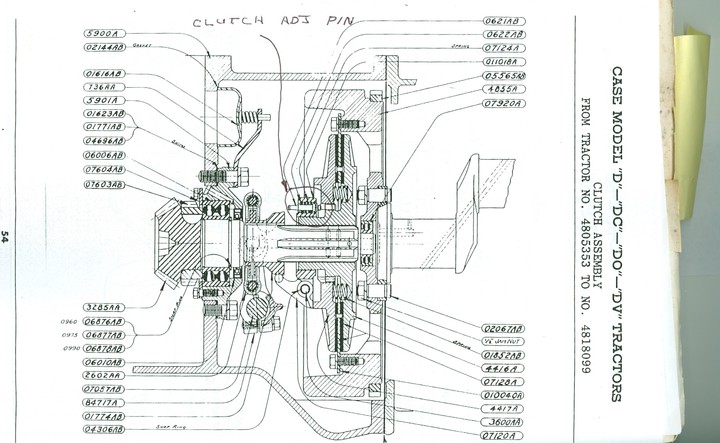

serial#5518546. SC.

non live pto is there any adjustment to this clucth noticed it sliping going uphill while raking hay and tonite i was planting wheat in a wet spot dry now

and it would slip almost to a stop when turning pulling a 10 ih 620 with hundred pounds or less of wheat seed.

second can you put a dry clutch in these?

thanks Loren

non live pto is there any adjustment to this clucth noticed it sliping going uphill while raking hay and tonite i was planting wheat in a wet spot dry now

and it would slip almost to a stop when turning pulling a 10 ih 620 with hundred pounds or less of wheat seed.

second can you put a dry clutch in these?

thanks Loren