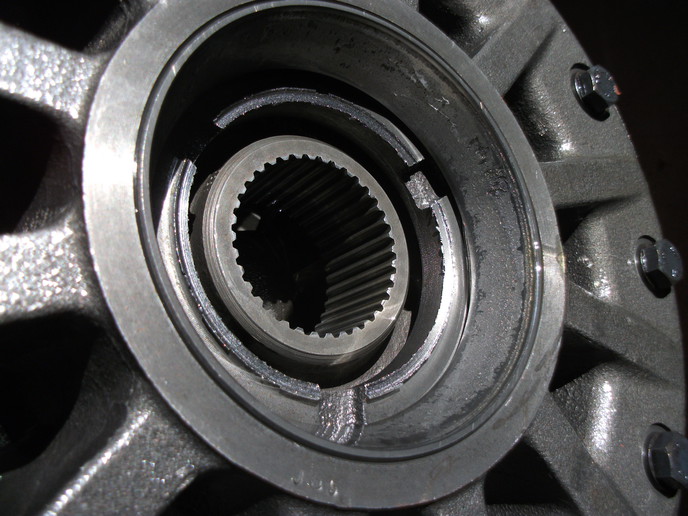

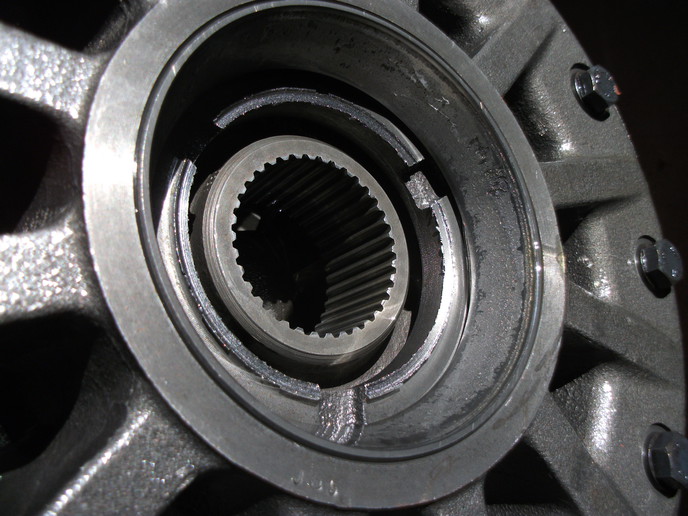

Even if you have serviced and drove 70 series tractors for over 40 years you can still get stuck with a bad one. I bought this tractor on a online auction. I should have taken the time and inspected it first. Oh well, water over the bridge now. I could see the axle housings had never been removed. Knowing sun gear failure in the final drives was a common problem on these tractors I decided to remove the axle housings and inspect them. Glad I did because the teeth were starting the flake off chips. I then pried on the differential carrier and found that to be to loose. So I then tore the back off the tractor and removed the carrier and found the RH brg to be badly damaged. With the carrier out I took that apart only to find it was broken also. Now it looked like it would take a small fortune to fix this thing. I was lucky that the area salvage yard had a excellent carrier assembly that they sold to me at a unbelievable low price. First pic is the bad carrier brg, second is the damaged carrier and third is the good used replacement. Rod.