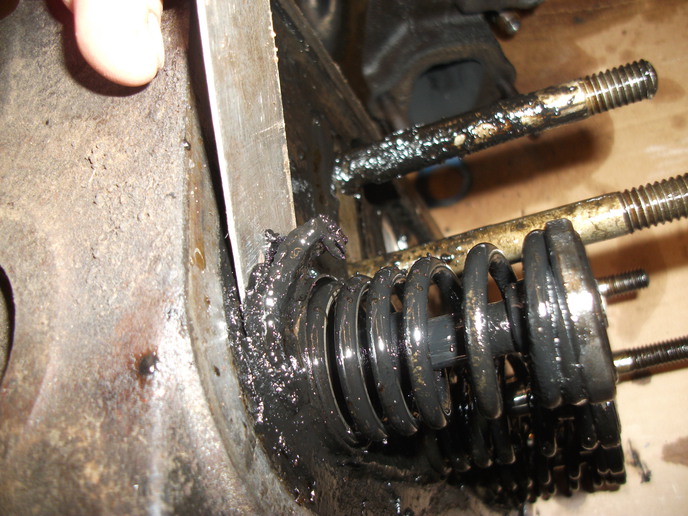

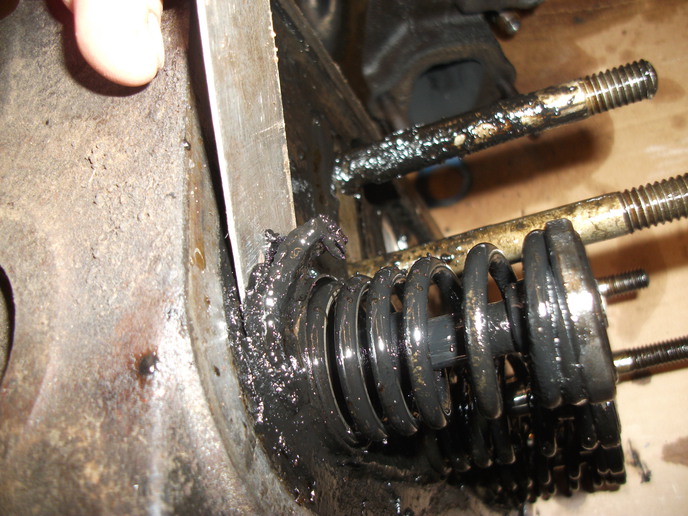

The most common spot for the 504 head gaskets to fail is on the front or back of head. In the first pic the pencil points at the erosion the fire ring in the headgasket caused to the head. These heads have to be surfaced to clean up that worn area if the new gaskets are going to have any chance of sealing for a while. One must remember the block has similar wear and that is not a easy or cheap fix, so if you do anything the heads must be good. This engine does not need a overhaul yet so hopefully the new gaskets will hold a couple years. The second pic points out the area where combustion gases like to sneak by the gasket and into the cooling system. When this happens coolant is forced out the overflow resulting in low coolant levels. The one pic shows good inserts from the oil passages in the gasket and on the right side shows failing inserts from coolant passages. For some reason the one's sealing coolant are falling apart. The cylinder pics show the first with normal wear for thousands of hours and the second pic shows the cylinder that the coolant has been leaking into and it does not look very good, could even have a possible broken top ring. This tractor only gets used to feed cattle a couple times a day or we would possibly replace that cylinder. The last pic shows the crud build up on the top of heads, I have never seen one this dirty. This tractor has close to 20,000 hrs and has been overhauled once. Rod.