Steve (DE)

Member

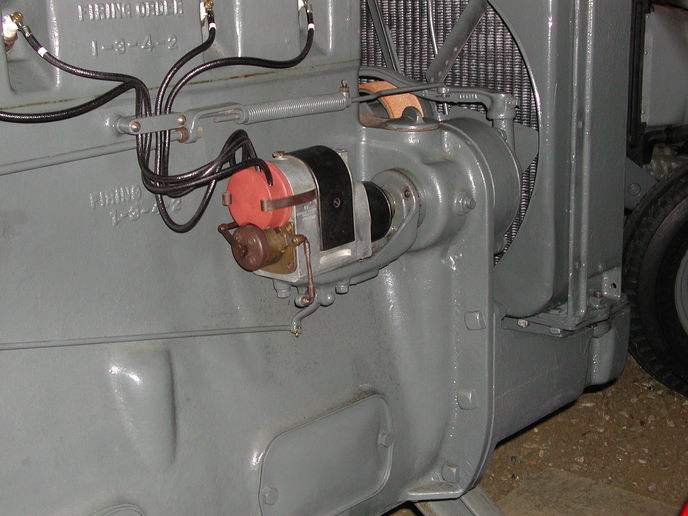

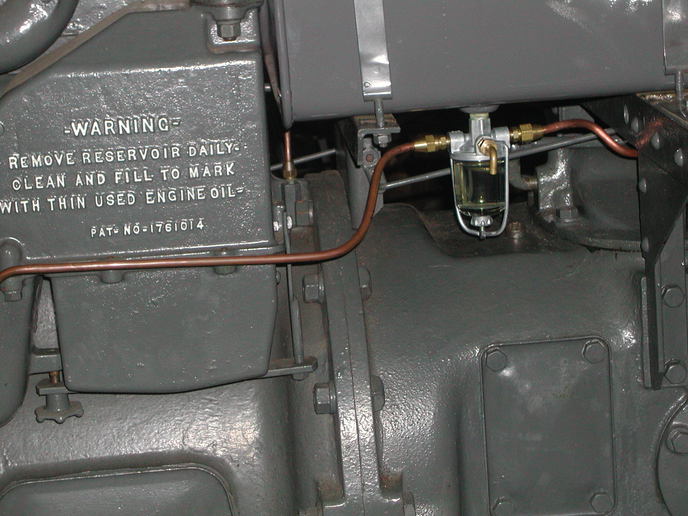

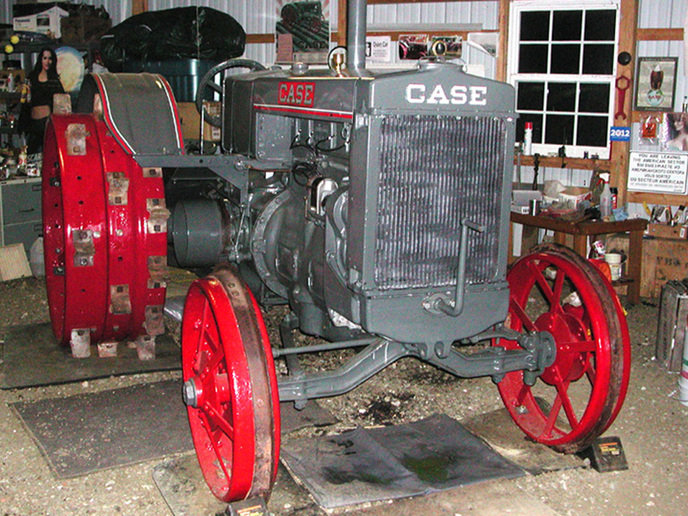

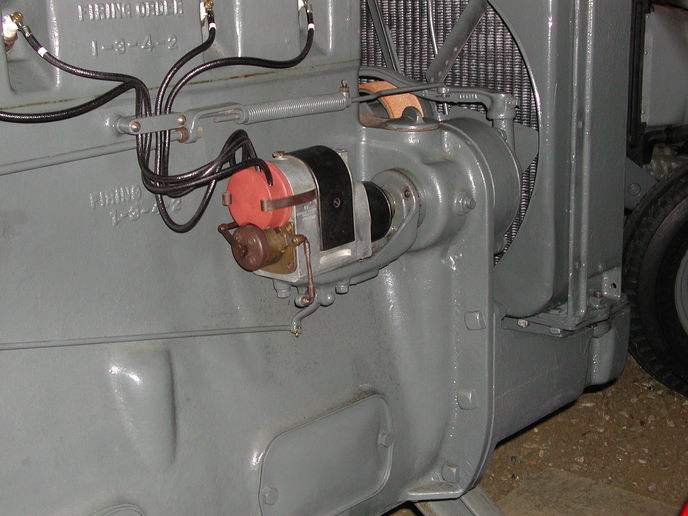

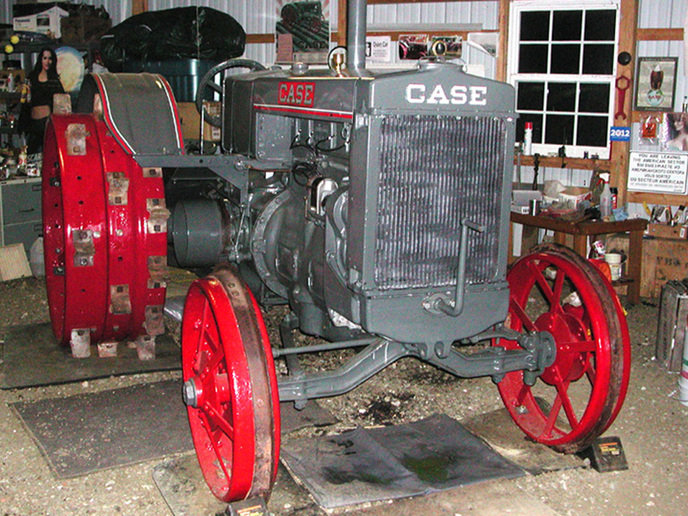

I posted a few weeks back, and couldn"t get even a pop out of this thing. Checked out all your suggestions and did get some things straightened out. Re-adjusted the timing. Checked to see that there was gasoline actually coming out of the carburetor drain valve when I opened it. Got a few loud pops somewhere along the way. Now with everything gone over a time or two it still won"t go. I sometimes get a small puff of smoke from the exhaust, but when I keep trying the cranking, that stops and it just sits there looking stupid (with me feeling stupid). Anybody got a list of things to check one at a time to fix this. Its too big to be a lawn ornament.