Adirondack case guy

Well-known Member

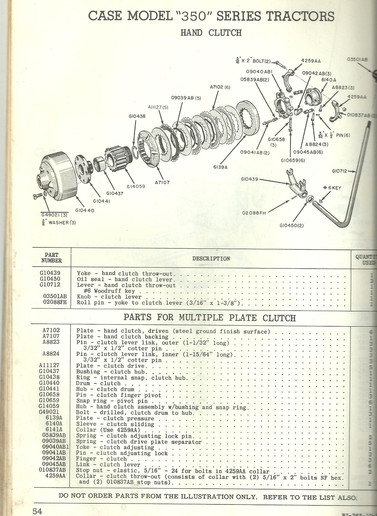

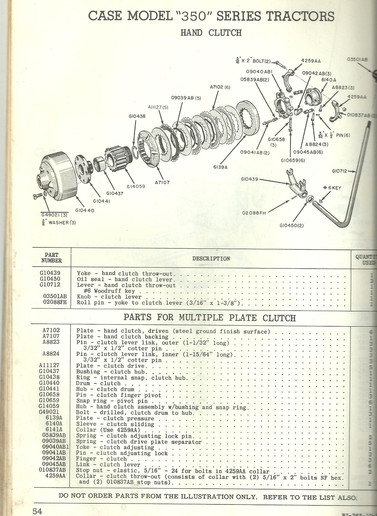

I think you are confusing drive and driven plates.

The cintered plates are the drivers, the steels are driven. In this pic, not from a 930, but same parts. there are 5 cintered plates, and 5 springs, and 6 steel driven plates. I believe that you have one too many springs, spacing them apart so they will not lock up.

Loren

The cintered plates are the drivers, the steels are driven. In this pic, not from a 930, but same parts. there are 5 cintered plates, and 5 springs, and 6 steel driven plates. I believe that you have one too many springs, spacing them apart so they will not lock up.

Loren