munson1086

Member

Hi everyone,

I have been making slow progress on my 53 DC. The whole time and money thing always gets in the way!! I just finished installing a new rubber seat spring last weekend.. what a difference! It's amazing; the seat had been welded solid for as long as I can remember. My next project I want to start on is new wiring, lights, and alternator.

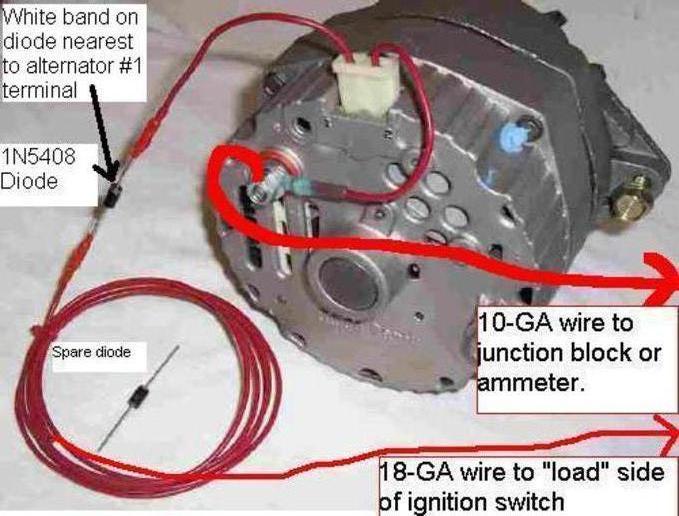

Soooo.... yet another question on the 12v conversion. I have read a bunch of material on this topic.. but still have a question. I have a DC with magneto and I want to keep the mag.. so distributor is not an option. Here is where my question is... do I need to install a separate ignition switch for the wire that goes to the #1 terminal on the alternator? I plan on installing the delco 10 si alternator. If anyone has a wiring diagram with a tractor with mag and alternator that would be great!

Thanks,

Matt

I have been making slow progress on my 53 DC. The whole time and money thing always gets in the way!! I just finished installing a new rubber seat spring last weekend.. what a difference! It's amazing; the seat had been welded solid for as long as I can remember. My next project I want to start on is new wiring, lights, and alternator.

Soooo.... yet another question on the 12v conversion. I have read a bunch of material on this topic.. but still have a question. I have a DC with magneto and I want to keep the mag.. so distributor is not an option. Here is where my question is... do I need to install a separate ignition switch for the wire that goes to the #1 terminal on the alternator? I plan on installing the delco 10 si alternator. If anyone has a wiring diagram with a tractor with mag and alternator that would be great!

Thanks,

Matt