Ken Christopherson

Well-known Member

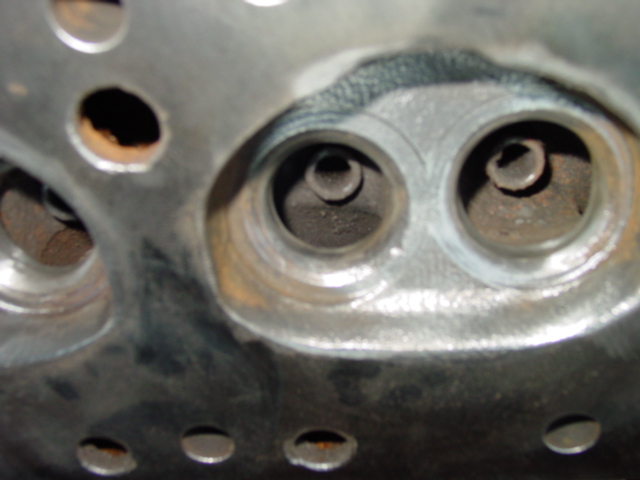

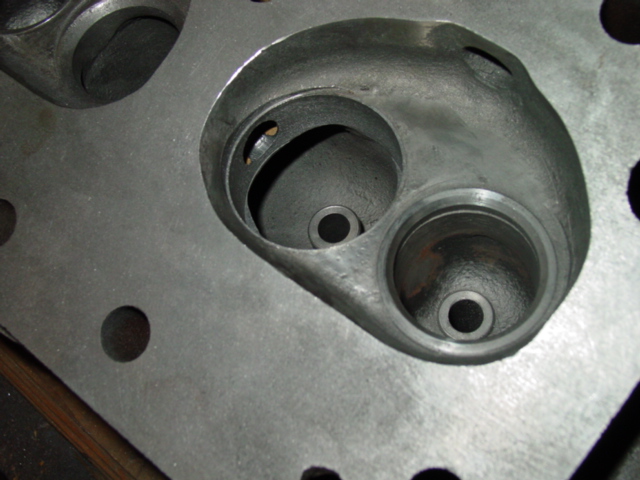

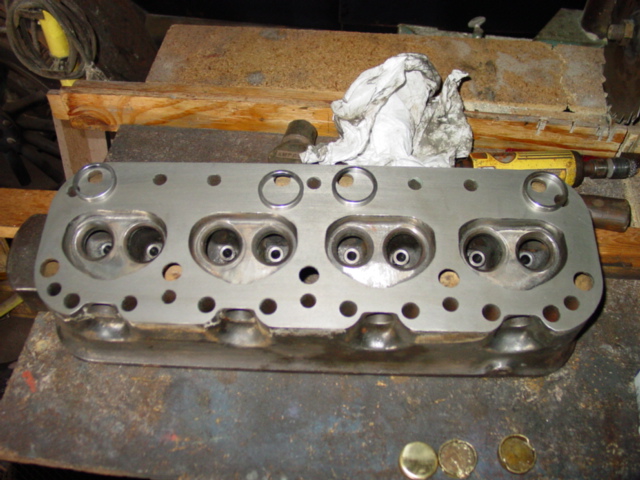

Well guys, I got the carb for that Allis WD all cleaned up and put in a new rebuild kit. (The photo enclosed is after I cleaned it, and cleaned the OLD parts). There was a lot of rust scale in the bowl. There must have been some water in it for some time at one point. Seems to be running really strong, but still has a pop/misfire coming from what I believe to be #1 exhaust valve/port. I'm thinking this tractor is good for an overall once-over. Head work, and probably a top end with 90-95 PSI in the cylinders (due to what I have gathered from you all).

Tractor does not smoke at all, though. I told him to run non-oxy gas in it and see how it pans out. For now, it seems to be running pretty good. (I apologize for the poor video quality - cell phone was all we had at the time).

Maybe a manifold leak as well? - but I can't seem to get any change in RPM when spraying it down with Carb Cleaner and propane near all manifold connections.

Allis WD Update Carb Rebuild

Tractor does not smoke at all, though. I told him to run non-oxy gas in it and see how it pans out. For now, it seems to be running pretty good. (I apologize for the poor video quality - cell phone was all we had at the time).

Maybe a manifold leak as well? - but I can't seem to get any change in RPM when spraying it down with Carb Cleaner and propane near all manifold connections.

Allis WD Update Carb Rebuild