loveshisallis

Member

Hello;

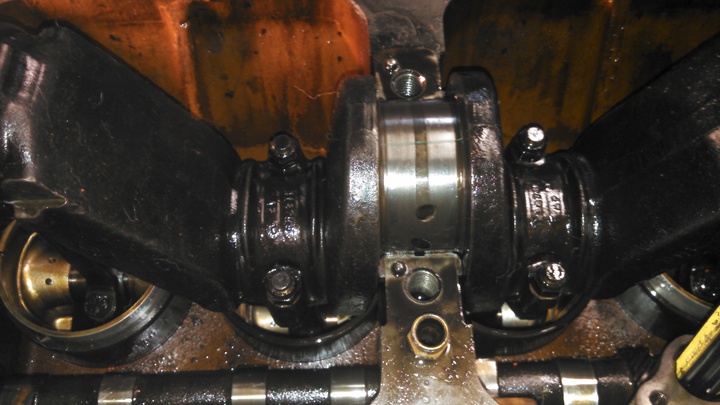

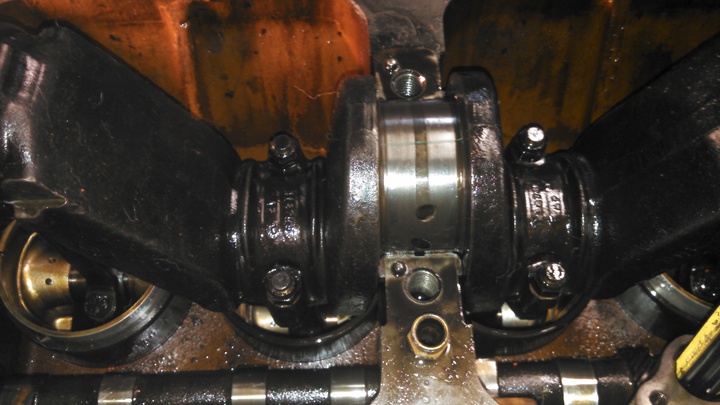

This is a partial repost of an earlier email. I have 1963 Series III D 17 which had two problems, 1. Took 5-8 seconds to develop full oil pressure, then fine. 2. A knock on startup that would last the same 5-8 seconds, then be fine. The final thing I can say is the the previous owner had lent it out to a neighbor once and the tractor come back three quarts low and also he had to install a new head gasket.

Got to working on the mill and here is the information. Check the first 2 mains (from the front) and they plasticgaged out to just over .003. The first rod checked at .0015. I could not quite catch my nail on the surface on the crank.

So one question I have is can that main bearing clearance (Book sez .0035 is upper limit)cause the problems I have listed?

Also opinions on the job invited.

Thank You

This is a partial repost of an earlier email. I have 1963 Series III D 17 which had two problems, 1. Took 5-8 seconds to develop full oil pressure, then fine. 2. A knock on startup that would last the same 5-8 seconds, then be fine. The final thing I can say is the the previous owner had lent it out to a neighbor once and the tractor come back three quarts low and also he had to install a new head gasket.

Got to working on the mill and here is the information. Check the first 2 mains (from the front) and they plasticgaged out to just over .003. The first rod checked at .0015. I could not quite catch my nail on the surface on the crank.

So one question I have is can that main bearing clearance (Book sez .0035 is upper limit)cause the problems I have listed?

Also opinions on the job invited.

Thank You