FreshEarthFarms

New User

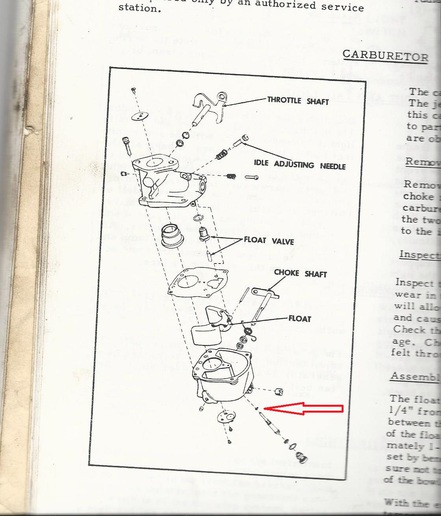

I've been struggling with getting my G working consistently this season. I'm hoping someone can help. The latest is the carb seems to drip

gas whenever I am cranking the engine. If it just sits with the fuel line valve open it doesn't drip gas. I can get it to start

occasionally but it runs really poorly and sputters to a stop shortly after starting. Then I can't get it to restart. I assume based on the

gas dripping that the engine is flooding. I've rebuilt the carb including a new float valve and seat. I've replaced the spark plugs,

points, condenser, coil and plug wires. The float is about five years old and doesn't have any fuel in it.

Anyone have any ideas on how to get this going? It ran great last season. It ran great for two days this season but no longer.

gas whenever I am cranking the engine. If it just sits with the fuel line valve open it doesn't drip gas. I can get it to start

occasionally but it runs really poorly and sputters to a stop shortly after starting. Then I can't get it to restart. I assume based on the

gas dripping that the engine is flooding. I've rebuilt the carb including a new float valve and seat. I've replaced the spark plugs,

points, condenser, coil and plug wires. The float is about five years old and doesn't have any fuel in it.

Anyone have any ideas on how to get this going? It ran great last season. It ran great for two days this season but no longer.